Bohai Valve Co., Ltd. Yongjia

Contact: Mr. Wang

Phone 577 -57796661 / 057796662

Fax 577 -67367855

Phone: 13806833242

E-mail: 258193218@qq.com

Address: Industrial Zone Oubei Puxi

PRODUCTS

Z40H

Product use:

Z40H gate valve is suitable for the American standard ANSI Class150 ~ 2500, PN20 ~ 42, JIS10 ~ 20 k, working temperature - 29 ~ 425 ℃ (carbon steel) and - 40 ~ 500 ℃ (stainless steel) of pipe in the name of the road, to truncate or on line in the medium. By using different materials, it can be applied to water, steam, oil, nitric acid, acetic acid, strong oxidation medium and urea.

Product features:

1. The product is designed and manufactured in accordance with foreign advanced standards, with reliable sealing and excellent performance. 2. Compact and reasonable structure design, beautiful shape. 3. Adopt wedge-type elastic gate plate structure, set rolling bearing with medium and large bore, easy to open and close. 4. The valve body has a complete variety of materials, and the stuffing and gaskets are reasonably selected according to the actual working conditions or user requirements, which can be applied to various pressure, temperature and media working conditions. 5. Adopt various domestic and foreign pipe fitting flange standards and flange sealing cover types to meet various engineering requirements and user requirements.

Product implementation standards:

Design and manufacturing: API 600; Flange dimensions: ANSI B16.5; Structure length: ANSI B16.10; Pressure ~ temperature: ANSI B16.34; Testing and testing: API 598

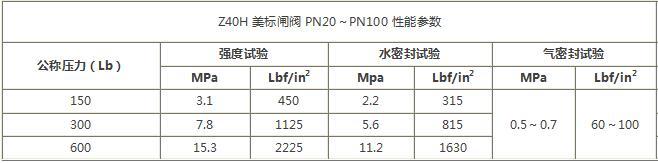

Product performance parameters:

Material of product parts:

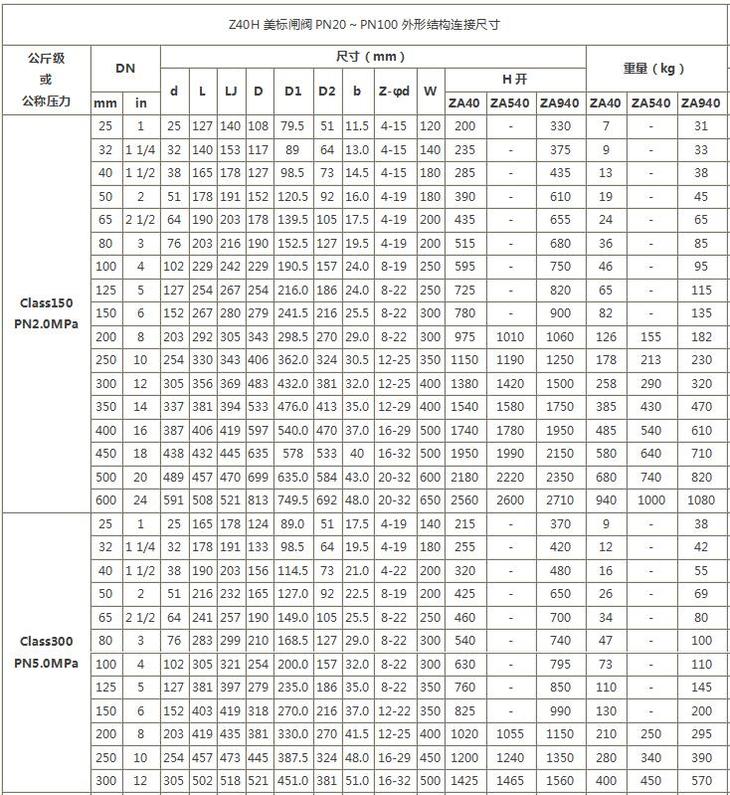

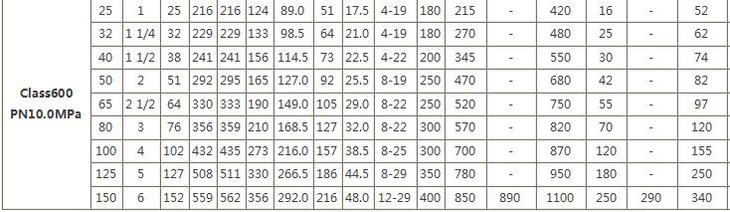

Product profile connection size:

Installation precautions and points:

Handwheel, handle and drive mechanism are not allowed to be hoisted, and collision is strictly prohibited.

2. Double gate gate valve shall be installed vertically (i.e. the stem is in the vertical position and the handwheel is at the top).

3. Gate valves with bypass valve should open bypass valve before opening (to balance pressure difference between inlet and outlet and reduce opening force).

4. The gate valve with drive mechanism shall be installed according to the specifications of the product operation manual.

5. If the valve is frequently switched on and off, lubricate at least once a month.

6. The installation position, height and inlet and outlet direction must meet the design requirements, and the connection should be firm and tight.

7. All kinds of manual valves installed on the insulated pipes shall not have downward handle.

8. The gate valve with drive mechanism shall be installed according to the provisions of the product operation manual.

9. Appearance inspection must be conducted before valve installation, and the valve nameplate should comply with the current national standard "general valve mark" GB12220. For valves with working pressure greater than 1.0mpa and with cut-off function on main stem pipe, strength and strict performance test should be conducted before installation. During the strength test, the test pressure is 1.5 times the nominal pressure, and the duration shall not be less than 5min. The valve housing and packing shall be qualified without leakage. During the strict test, the test pressure was 1.1 times of the nominal pressure. The test pressure shall meet the GB50243 standard for the duration of the test, and the valve disc sealing surface shall be qualified without leakage.

| 今天是 |

|

Copyright 2013 Bohai Valve Co., Ltd. Yongjia LUOTUO All Right Reserved. Address: Yongjia County, Wenzhou City, Zhejiang Province town of North ICP No.: ICP 12045727 No. -1 |

- LINK:

- Low-speed centrifuge hot press sintering furnace High Speed Microcentrifuge vacuum degreasing sintering furnace Refrigerated high-speed centrifuge vacuum hot press furnace PRP(platelet rich plasma) centrifuge vacuum tube furnace Large capacity centrifuge controlled atmosphere furnace Cyto Centrifuge high temperature vacuum furnace